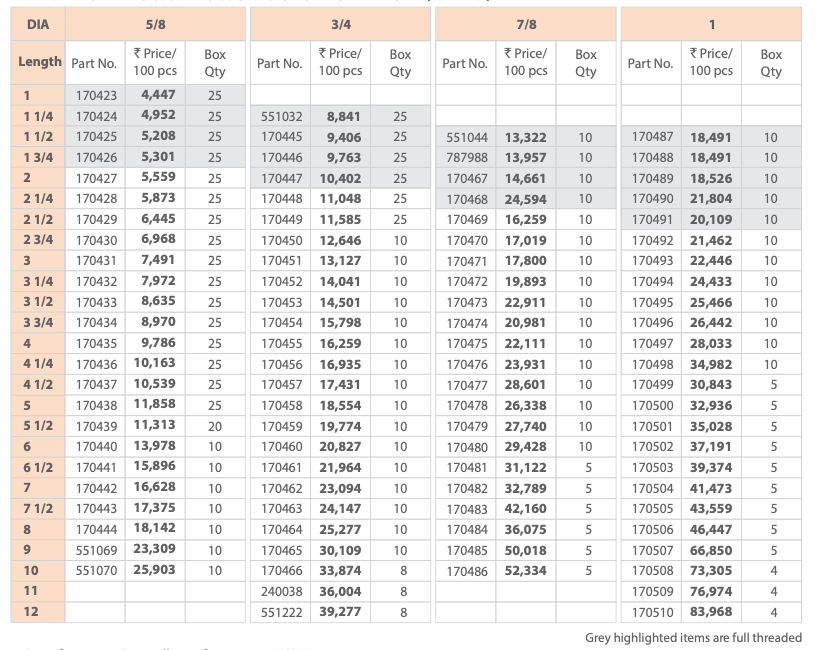

HEX head bolt

Hex Head Bolts are the most commonly used type of fastener, recognized by their six-sided head, which allows for efficient tightening using a spanner or socket wrench. Known for their strength, versatility, and ease of use, these bolts are ideal for structural and heavy-duty fastening in construction, machinery, and engineering projects

Available in both full and partial thread variants, Hex Head Bolts are manufactured from materials such as mild steel, high-tensile steel, stainless steel (SS 304/316), and alloy steel, and offered with surface finishes like zinc plating, hot-dip galvanizing, black oxide, and PTFE coating. These bolts are produced in accordance with international standards such as DIN 933, ISO 4014/4017, BS 1083, and ASTM A325.

Sizes are as per your Specifications & Drawing*

Strong Grip. Simple Drive. Reliable Every Time.

Extra long nuts, also known as coupling nuts or extended hex nuts, are commonly used in mechanical, structural, and heavy engineering applications. Their primary function is to connect two male threaded rods or to provide deep thread engagement where high clamping strength is essential. These nuts are particularly useful in:

Steel fabrication

Heavy machinery assembly

Bridges and structural supports

Wind turbine installations

Automotive and aerospace components

Pipeline and oil & gas equipment

Due to their extended length, they offer greater thread engagement compared to standard nuts, minimizing the risk of loosening due to vibration or load stresses.

Extended Thread Depth: Offers superior load distribution and grip over longer threaded sections.

High Tensile Strength: Manufactured from carbon steel, alloy steel, or stainless steel, depending on the requirement, for superior performance under high-stress environments.

Precision Machining: Each nut is precisely machined using CNC technology to ensure tight tolerances and perfect thread alignment.

Corrosion Resistance: Available with coatings like black oxide, hot-dip galvanizing, or zinc plating to resist corrosion and environmental wear.

Customizable Dimensions: We can manufacture extra long nuts in various sizes, diameters, and thread standards (metric, UNC, UNF, etc.) as per client specifications.

Enhanced Holding Power: The extended length allows for a larger surface area contact, reducing stress and the likelihood of failure.

Durability in Harsh Conditions: Ideal for outdoor or high-vibration settings where standard nuts may fail.

Versatility: Suitable for both temporary and permanent joints across diverse industries.

At our company, we don’t just supply hardware — we engineer reliable fastening solutions tailored to your project needs. Whether you’re building infrastructure or assembling precision machinery, our extra long nuts are the dependable choice for strength and longevity.

Let us know your custom requirements, and we’ll deliver precision-engineered nuts made to exceed expectations.

Applications

- Construction & Steel Structures

- Heavy Machinery & Equipment

- Automotive & Trucks

- Oil, Gas & Petrochemical

- Power Plants & Renewable Energy

- Railways & Infrastructure